By Paul R Salmon FCILT,FSCM,FCMI

Few products spark stronger reactions than Marmite. Since its creation over a century ago, the iconic yeast extract spread has divided the world into lovers and haters. But behind the marketing campaigns and heated breakfast table debates lies a fascinating supply chain story — one built on by-products, brand resilience, and global logistics.

This article explores how Marmite moves from brewery by-product to breakfast staple, the challenges it faces, and what supply chain leaders can learn from its unique journey.

1. From Brewery Waste to National Icon

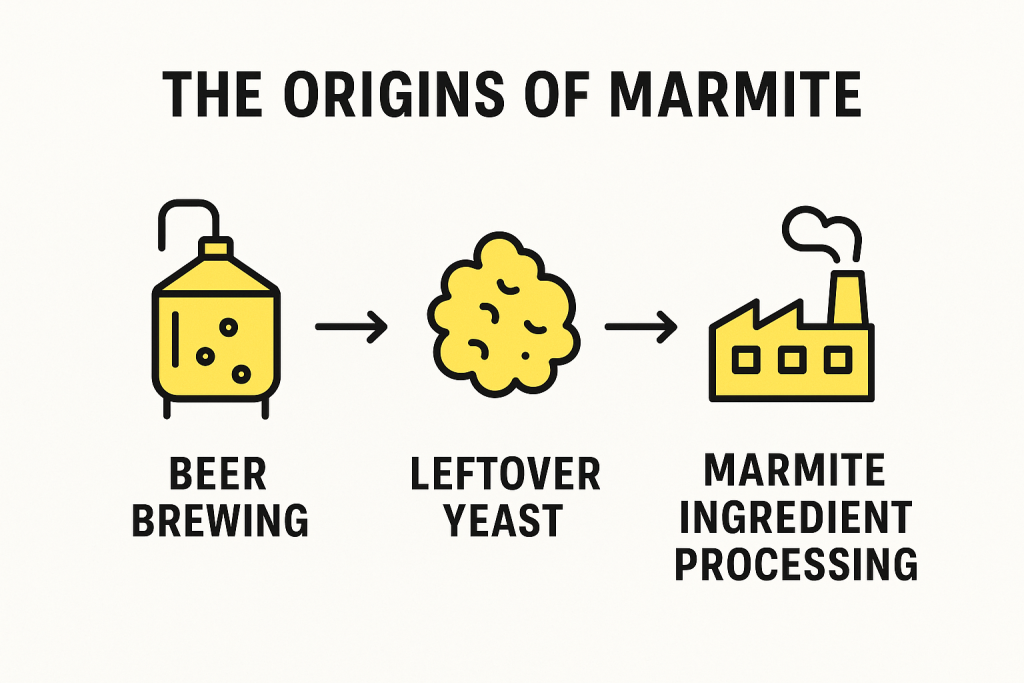

Marmite’s origins are rooted in ingenuity. In the late 19th century, German scientist Justus von Liebig discovered that brewer’s yeast — a by-product of beer brewing — could be concentrated and eaten.

Supply Chain Starting Point: Marmite begins with the brewing industry. Breweries generate the yeast extract, which forms the raw input. Dependency Risk: If brewing volumes drop, Marmite supply contracts. During the COVID-19 lockdowns, when pubs closed and beer production declined, Marmite supplies became scarce — a stark reminder of upstream reliance.

“The Origins of Marmite”

2. Processing: Turning By-Product into Brand

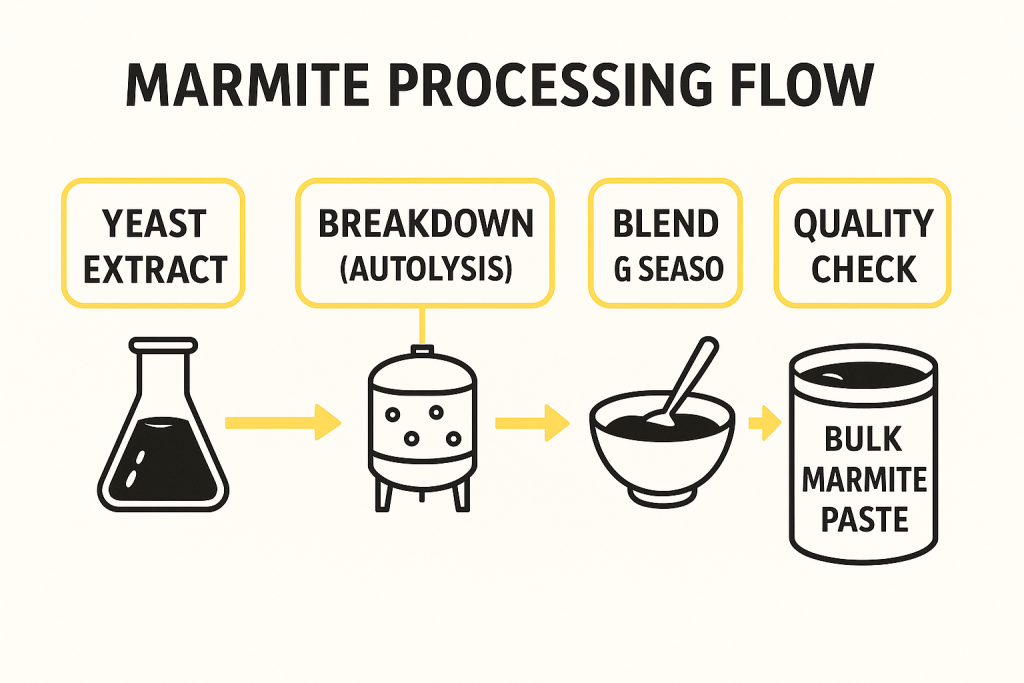

Yeast extract is far from consumer-ready. It undergoes a specialist processing chain:

Concentration & Paste Formation – Brewer’s yeast is broken down using autolysis, releasing proteins and vitamins. Blending & Seasoning – Added vegetable extracts and spices give Marmite its distinctive taste. Quality Control – Ensuring consistency of flavour and nutritional content is critical to maintain brand reputation.

This stage exemplifies the circular economy — waste transformed into a high-value, branded product.

“Marmite Processing Flow”

3. Packaging: More Than Just a Jar

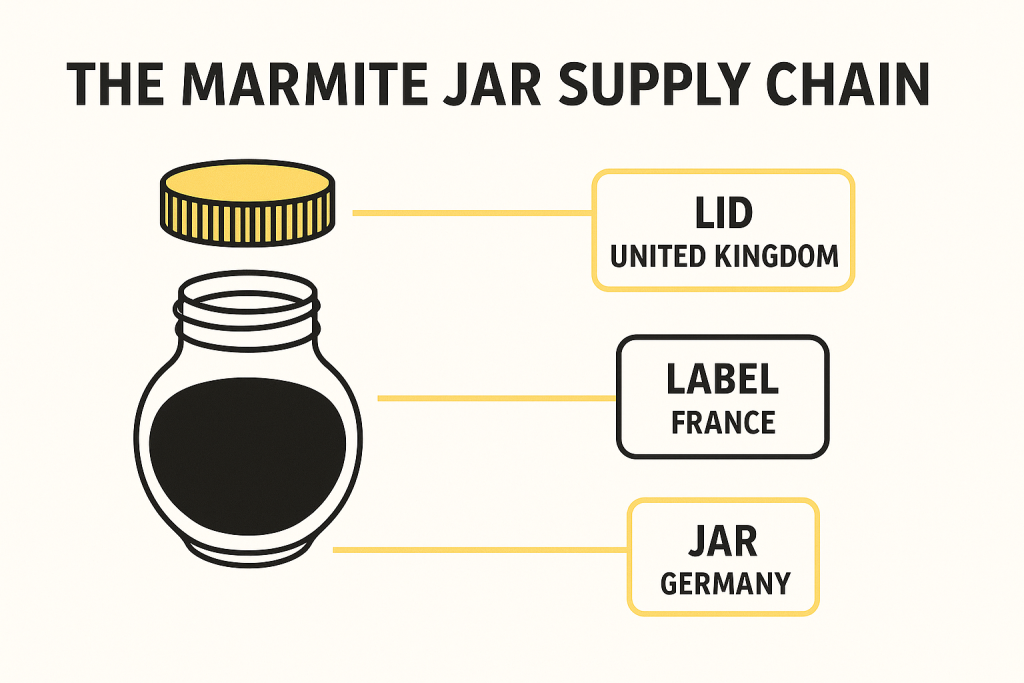

The iconic brown jar with its bright yellow lid is instantly recognisable. But maintaining that look brings supply chain complexity:

Glass Production – Energy-intensive and subject to fluctuations in raw material and energy prices. Lid Manufacturing – Plastic moulding, colour consistency, and fit must be precise. Labelling & Branding – Marmite’s brand equity is tied to its packaging; even small changes can spark consumer backlash.

Sustainability pressures are driving packaging innovation, but the cost vs. tradition debate looms large. Would Marmite lovers accept a pouch or carton instead of a jar?

“The Marmite Jar Supply Chain”

4. Distribution: From Factory to Fanatics

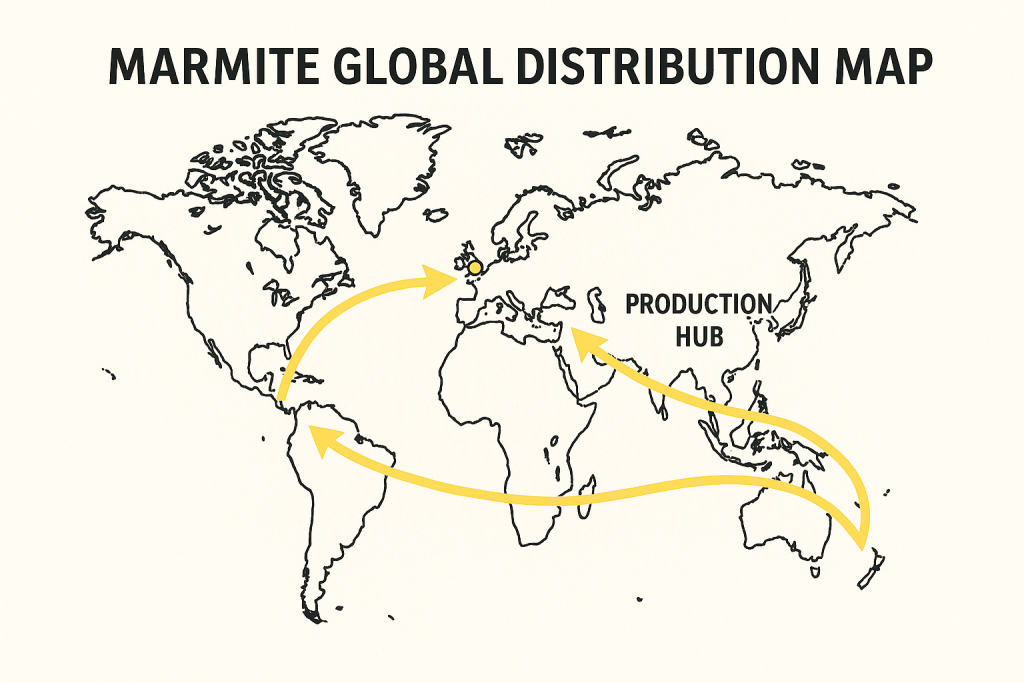

Marmite is produced in the UK (most famously at the Burton-on-Trent site), but its reach is global:

Domestic Retail: Supermarkets, convenience stores, and online orders dominate. Export Markets: New Zealand, South Africa, and Australia are particularly strong Marmite-loving nations. Trade Frictions: Post-Brexit customs checks and tariffs have added complexity for exports.

Its distribution chain balances high-volume supermarket replenishment with niche global shipments for expat communities and brand loyalists.

“Marmite Global Distribution Map”

5. Resilience Lessons: Scarcity and Substitution

Marmite has faced disruption before:

COVID-19 Yeast Shortage (2020) – With breweries closed, yeast extract supplies fell sharply. Supermarkets faced empty shelves. Pricing & Sourcing Shocks – Glass shortages and energy price spikes have affected jar production.

Unlike many FMCG products, Marmite has no easy substitute. Its uniqueness makes resilience planning essential. Lovers will wait or even pay more — but only up to a point.

6. What Supply Chains Can Learn From Marmite

Marmite’s story provides valuable lessons for supply chain professionals:

By-Product Dependency is Double-Edged – Circular supply chains are sustainable, but they rely heavily on upstream industries. Brand Identity Adds Supply Chain Rigidity – Iconic packaging can limit flexibility in sourcing or design changes. Global Niche Markets Require Agility – Even small-volume export markets matter for brand loyalty. Transparency Builds Consumer Resilience – When shelves were empty, consumers appreciated knowing why (beer production shortfall) rather than just seeing stockouts.

Conclusion: Love It or Hate It, Supply Chain is the Real Hero

Marmite is more than a spread — it’s a supply chain case study in circular economy innovation, brand resilience, and dependency risks. From brewery floors to breakfast tables, its journey shows how fragile yet ingenious supply chains can be.

Whether you love it or hate it, you can’t ignore the supply chain that keeps Marmite on the shelf.

Leave a Reply